Pfadnavigation

- Startseite

- Enzymes

cdmo services

Enzymes

EUROAPI has published a white paper describing the case study of the recombinant transaminase production process development, from enzyme screening through miniaturized system to final scale-up in pilot plant (10m3), which was performed by the R&D department of EUROAPI Brindisi.

The results described in this white paper support the end-to-end development approach applied by the EUROAPI R&D team to recombinant enzyme production. These results enable a complete process development train, from lab to pilot scale with batch manufacturing up to 10m3 scale.

For more information

Contact us

Our Brindisi site holds equipment and upstream (USP) & downstream (DSP) processing capacities for enzyme production from lab scale development to pilot manufacturing (10m3):

-

1. Small scale process development

-

2. Upstream and process development capacity

-

3. Downstream development at lab-scale

-

4. Kilo-lab equipment for kilo-batch manufacturing (pilot scale)

-

5. Analytical method development and support

1. Small scale process development, enzyme and strain screening

- Dedicated laboratory and equipment for small scale process development

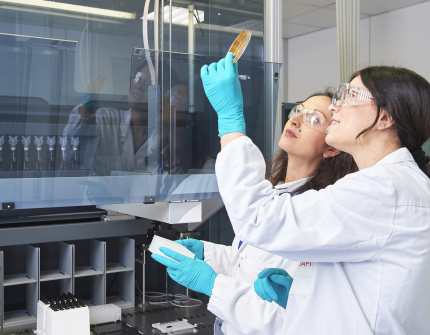

- Automated liquid-handling systems for miniaturized processes

- 2 high-throughput screening automated platforms

- Automatic plating station

- Automatic colony picking station with appropriate software and databases

2. Upstream and process development capacity suitable for high cell density fermentation (e.g., E. coli and P. pastoris) and filamentous fungi and bacteria

- 1L-scale parallel bioreactor system

- Fermenters: 20L-scale, 30L-scale and 40L-scale

- Cell-container

- Pure oxygen line supply at lab scale

- Off-gas analysis systems

3. Downstream development at lab-scale

- Cell lysis equipment for intracellular product recovery

- Centrifugation system: Ultracentrifuge

- Filtration system (TFF)

- Microfiltration (ceramic)

- Ultrafiltration (spiral wound and cassette)

- Chromatographic systems for protein purification (FPLC)

- Spray dryer and freeze dryer technologies

4. Kilo-lab equipment for kilo-batch manufacturing (pilot scale)

- Upstream

- 600L no-GMP bioreactor

- 10m3 no-GMP bioreactor

- Downstream

- Cell lysis equipment for intracellular product recovery

- Disk stack centrifuge

- Microfiltration & Ultrafiltration (TFF multipurpose system)

- Chromatographic systems for protein purification (FPLC)

- Freeze-drying technologies

5. Analytical method development and analytical support at all the steps of process development and manufacturing

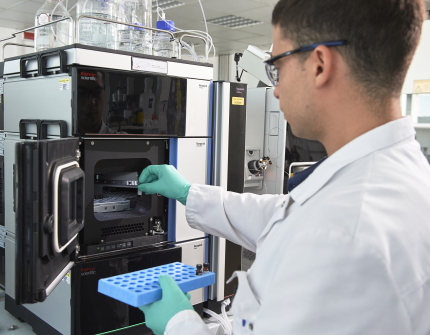

- HPLC and UPLC method development for products, impurities, metabolites quantification

- Triple quadrupole mass spectrometer

- Enzymatic activity assay development and quantification

- Analytical methods for protein expression quantification